Quality Control Process

Quality Control System

Supplier Control

Incoming Goods Inspection

IPQC

Final Inspection

In-processing Products Quality System

Management Analysis

Quality Test

JURID Compressibility Tester

Sheer Strength Tester

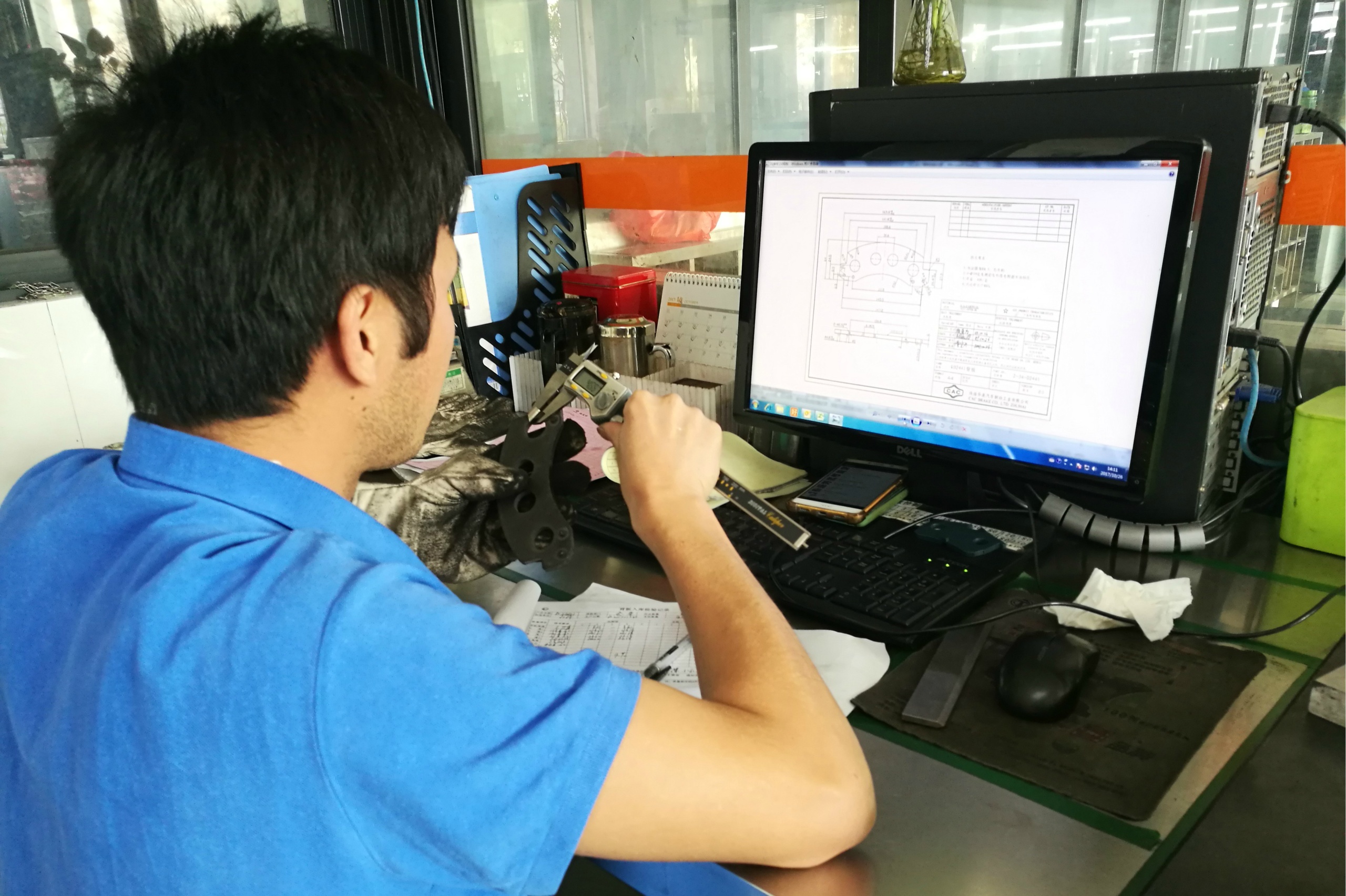

Dimension Inspection

SAE J661 Tester

Hardness & Density Tester

Salt Spray Tester

T-pull Tester

Krauss Tester

Incoming Test

Supplier material test: All the materials that arrive at our factory from our suppliers are tested before they are stored and put into production. This is to ensure we use good quality material.

Incoming inspection: All the materials that are used for production are inspected before using, in order to ensure everything used is qualified.

New material analyzing: If we change the supplier, then all the materials from a new supplier are examined and tested before using for production.

Process Inspection

Before mass production, the brake pads need to go through various physical and chemical testing to ensure the materials that were used meet the requirements and are qualified. During production, parts in each process are inspected.

Physical test: There are various physical test equipment to perform these tests. For example, the shear strength equipment is to test the friction material so that it does not fall off from the backing plate during braking. The heat swell & transfer tester would test whether the brake pad can work normally under extreme conditions such as very high temperature etc.

Chemical test: This is to test whether the brake power would not be affected even when the brake pad is exposed to acid or alkaline substances.

Dimension test: This is to ensure the size of brake pads in order to fit into the caliper perfectly.

Density test: This is to test the density of the brake pads and to ensure they work efficiently and properly.

Rockwell Hardness Test Apparatus: Used for hardness inspection of lining.

Strength Shearing Curing Over: This is to test the adhesive strength between the pad and back plate under a high temperature treatment.

T-Pull Test apparatus: For shim bonding force inspection or clip pull off force.

Compressibility Tester: To test the compressibility under high temperature.