Manufacturing Process

Manufacturing Process

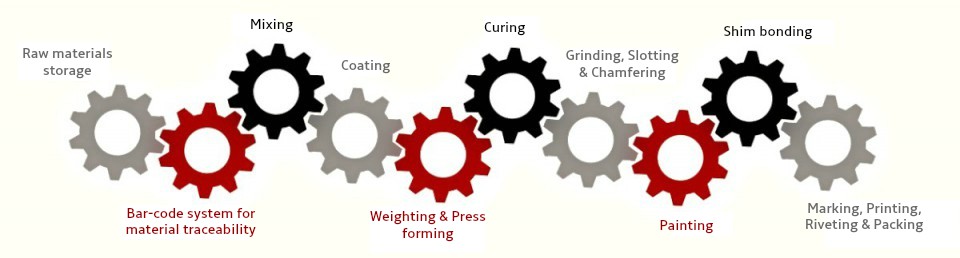

Brake Pad Production Process:

We apply the incoming inspection, climate control, barcode control, first in – first out and shelf time control to ensure we use the correct and perfect material to produce brake pads.

Raw materials storage:

After the incoming inspection, the qualified material is stored at a constant temperature and humid environment. (Climate control)

Bar-code system for material traceability:

Each material has its own barcode, once the barcode matches, only then does the door of storage tank open. This process ensures that the right material is used.

Mixing:

Friction materials are combined with various materials which are required to be mixed up before production.

Coating:

Glue is coated on the backing plate so that the friction material can stick to the backing plate.

Grinding, Slotting & Chamfering:

This process improves the performance of the brake pad and also improves its look.

Weighting & Press forming:

Backing plate and friction material bond together under high temperature.

Painting:

Brake pads are painted with blue or red color according to the client’s requirements.

Marking, Printing, Riveting & Packing:

This process marks the logo, prints some production details on the brake pad and rivets the accessories.

Curing:

Again, brake pads are put under high temperature to strengthen and ensure they can perform under extreme conditions.

Shim bonding:

Shims are placed on the brake pad.

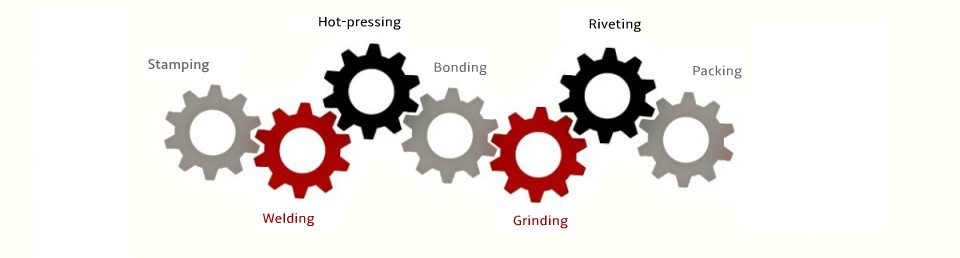

Brake Shoe Production Process:

When it comes to Asimco brake shoes, a multitude of factors are perfectly synchronized with each other with great care to ensure highest quality brake shoes with excellent friction stability.

Stamping:

There are two parts of a brake shoe, bare brake shoe, and brake line. The bare brake shoe is made of steel. Therefore, the steel first needs to be stamped and from there different shapes of bare brake shoes are formed according to different items.

Welding:

The bare brake shoe also consists of two parts. The welding process is to form them together.

Hot-pressing:

The brake lining needs to be put under high temperature for a few hours in order to have a stable performance under extreme real-life conditions.

Bonding:

In this process, the brake lines and the bare brake shoes are put together in normal temperature and also a few hours under high temperature to strengthen the performance.

Grinding:

This process improves the performance of the brake shoe and also improves its look.

Packing:

After a final test, all the finished products are packed.

Riveting:

This process assembles needed accessories on the brake shoe.